-

Fiber Laser Marking Machine

-

Integrated Laser Marking Machine

-

Desktop Laser Marking Machine

-

Split Laser Marking Machine

-

UV Laser Marking Machine

-

Handheld Laser Welding Machine

-

Portable Laser Marking Machine

-

CO2 Laser Marking Machine

-

Green Laser Marking Machine

-

Jewelry Welding Machine

-

Online Laser Marking Machine

-

Fiber Laser Continuous Welding Machine

-

Laser Spot Welding Machine

-

YAG Laser Welder

-

Galvo Laser Welder

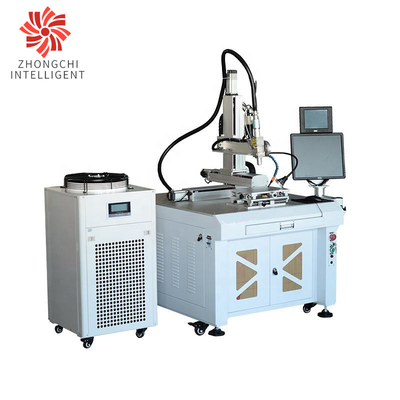

1080nm Manual Automatic Fiber Laser Welding Machine / Laser Beam Welding Machine RS232

| Place of Origin | Shenzhen,China |

|---|---|

| Brand Name | ZHONGCHI |

| Certification | CE / ISO / FDA |

| Model Number | LRL-LX |

| Minimum Order Quantity | 1 UNIT |

| Price | Negotiable |

| Packaging Details | Wooden Case Packing |

| Delivery Time | 10-15 days after payment |

| Payment Terms | L/C, T/T, D/A, D/P, MoneyGram,PayPal |

| Supply Ability | 9000 Units per Month |

| Condition | New | Place Of Origin | Shenzhen,China |

|---|---|---|---|

| Brand Name | Zhongchi | Warranty | One Year |

| Cooling System | Water Cooling | Product Name | Fiber Laser Continuous Welding Machine |

| Welding Mode | Continuous Welding | Application | Electronic Industry, Automotive Industry, Manufacturing Industry,etc |

| Emission Wavelength | 1080±5nm | Laser Classification | Optical Fiber Laser |

| High Light | Manual Automatic Fiber Laser Welding Machine,1080nm Automatic Fiber Laser Welding Machine,Laser Beam Welding Machine RS232 |

||

Laser Spot Welder Manual Metal Welding Continuous Automatic Fiber Laser Welding Machine Laser Beam Welding Machine

Product Description

Laser welding machine is one kind of processing method of welding materials with high energy density laser beam as heating source. It has the advantages of simple operation, beautiful weld seam, fast welding speed and no consumables.

In recent years, due to the continuous development of materials, technology and fabrication process, laser welding has been widely used in the welding of plastics, metals, etc. Besides, the laser welding machine will replace traditional welding methods ( such as argon arc welding) in automobiles, sensors, electronics industry.

Hand-held laser welding machine install hand-held welding head, which is similar with argon arc welding machine. It is flexible and simple operation, suitable for small batches orders. The laser welding machine can be widely used in cabinet kitchen and bathroom, stair elevator, shelf, Oven, stainless steel door and window guardrails, distribution boxes, stainless steel home and other industries complex and irregular welding process.

![]()

Features

1. The laser beam quality is excellent, the welding speed is fast, and the welding seam is firm and beautiful, bringing users an efficient and perfect welding method;

2. Industrial PC control, the workpiece can be moved on a plane trajectory, and any plane graphics composed of welding points, straight lines, circles, squares or straight lines and arcs can be used;

3. High electro-optical conversion rate and low energy consumption, long-term use can save a lot of processing costs for users;

4. The equipment has high reliability and can process continuously and stably for 24 hours to meet the needs of industrial mass production and processing;

Specifications

| Laser Model | LRL-LX1000W/LRL-LX1500W/LRL-LX2000W |

| Power | 1000W/1500W/2000W(Optional) |

| Output Power Stability | <3% |

| Center Wavelength | 1080±5nm |

| Way of Working | Continuous Working |

| Max Modulation Frequency |

5KHz |

| Red Light | Provided |

| Power Adjustment Range | 10-100% |

| Beam Quality | 1.1m² |

| Power Instability | ≤2% |

| Transmission Fiber Core Diameter | 25/50/100 um(Optional) |

| Minimum Spot | 0.2mm |

| Fiber Length | 20m |

| Control Mode | External RS232/External AD |

Applications

Applicable Industries:

1.Manufacturing Industry.

Laser welding technology is widely used in auto industry.

2.Digital 3C industry

Laser welding has been widely used in the digital 3C industry, especially in the mobile phone microelectronics industry.

3.Medical industry

The welding seam of the laser welding machine for medical equipment is smooth and beautiful, and will not cause deformation of the welded product.

FAQ

1. Q: Are you a manufacturer or a trading company?

A: We are a manufacturer established in 2017 ,now in Shenzhen China. Committed to providing the

majority of users with economic, high-quality laser equipment. Welcome to our factory.

2. Q: How long does it take to learn the laser?

A: The software is easy to learn with teaching video, also we can help you to learn the laser online. Usually it will take a few hours to operate the laser ,But it will take a bit of trial and error to learn what speed and power settings to use with different materials. So we include a comprehensive guide with your system that has recommended speed and power settings for various materials with which you will be working.

3. Q: Will the laser machine be safe during transport?

A: (1) Inner: plastic stretch film and white foam.

(2)Middle: small pieces of wood and screws.

(3)outside: standard export wooden case. So,the laser machine will send to you safely. In case the machine was damaged , please contact us ,We will process the replacement as soon as possible to ensure that it arrives in time .

4. Q: What should I do when something goes wrong with the laser?

A: We offer a one-year warranty. In warranty, we will provide the broken items free of charge.Beyond the warranty period, we still provide maintenance service.

5. Q: How deep can it engrave into metal?

A: All metals can be engraved into with some depth; However, some metals are more amenable to depth engraving. Softer aluminum material will engrave with depth with only a few passes. The best way to test your material is with our Applications Lab.